Last month, I explored how little we know about carbon emissions.

When companies say they are measuring their emissions, they are usually talking about the carbon produced by their own operations and energy use. These are called Scope 1 and Scope 2 emissions.

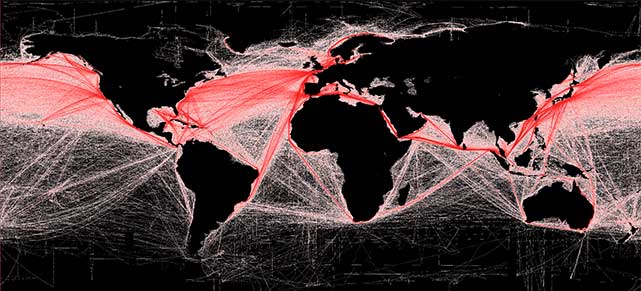

But there is a significant chunk of carbon that isn’t accounted for by these measurements. Scope 3 emissions include everything from transportation, emissions created in the supply chain, and the use of products in the consumer’s home.

The emissions are difficult to measure, but most global corporations have a responsibility to measure them because the vast majority of their emissions come from their supply chains, said Dexter Galvin, head of supply chain at CDP.

“The only companies that can avoid it are oil and gas, utilities and chemicals, because these are the only sectors where scope 1 and 2 emissions are vastly larger than scope 3. Everybody else has a responsibility to engage their supply chains. Otherwise, they’re not really reporting their emissions,” he said.

But simply measuring Scope 3 emissions isn’t enough. Companies also need to collaborate with their suppliers to make sure they can make the necessary changes on the ground. A new report shows neither companies nor suppliers have been doing enough to make this happen.

“The message is unambiguous: suppliers in major economies in both the developed and developing world are underperforming,” says Supply Chain Sustainability Revealed: A country comparison released today by CDP, a non-profit organization that works with investors, companies and governments on environmental disclosure.

The report asked 3,400 suppliers in 11 key markets to answer a questionnaire about how they are addressing climate and water risks, making it the largest existing data set on climate risk in the global supply chain.

The results show that suppliers are becoming slightly more serious about tackling climate change. Last year, 48 per cent of suppliers set emissions targets, up from 44 per cent in 2013.

France, the U.K., Spain and Germany have the most well-prepared and sustainable supply chains, even though they are exposed to relatively low climate risks. Japan is the only country where suppliers are well equipped to respond to high climate risks.

The bad news is that other key metrics are stalling. The proportion of companies that responded to this year’s CDP questionnaire is lower than last year. And even though more companies responded to the questionnaire than ever before, the number of suppliers that are taking action to tackle climate change stayed at 62 per cent from the previous year.

In other words, more companies are setting targets, but fewer are working to actually meet them.

This stagnation could have something to do with the fact that the amount of collaboration between companies and suppliers also fell back last year. Only 50 per cent of suppliers engaged with partners on the supply chain – a drop from 56 per cent in 2013.

Companies that engage directly with one or more of their suppliers are almost twice as likely to reduce their emissions and are even more likely to see a financial return from their low-carbon investments.

This is a fairly common sense lesson: companies can only tackle climate risks that are outside of their control if they are willing to delve into their supply chains and work with suppliers to solve their problems.

Unfortunately, many companies are intimidated by their supply chains. I wrote about health and safety in the garment industry last October and found that many companies were unwilling to take up the task of auditing their entire supply chains, claiming it was too daunting.

But CDP’s study shows that many suppliers – particularly in China and India – are eager to work with companies and other suppliers to reduce their carbon emissions.

In both countries, suppliers are calling out to their customers to support their investments in low-carbon technologies, said Galvin. And when companies answer this call, they get the highest returns on investment because there is still so much low-hanging fruit in these markets when it comes to carbon reductions, he said.

BT Group, one of the world’s largest multinational telecommunications companies, began tracking its carbon emissions in 1992, and has in the past few years also focused on supplier engagement to drive down supply chain carbon emissions.

To understand its Scope 3 emissions, BT Group paired economic modeling techniques with CDP data to get a bird’s eye view of the climate risk in its global supply chain, which includes thousands of suppliers around the world.

That analysis showed a surprising reality: 66 per cent of the company’s carbon emissions came from their suppliers, 29 per cent came from consumers’ use of their products and only 5 per cent was directly attributed to the company’s operations.

With this knowledge in hand, the company began engaging its top 20 suppliers on a one-on-one basis to get more information about their activities and to help them develop best practices to reduce their emissions, said Gabrielle Giner, Environmental Sustainability Programme Manager at BT Group.

Once a year, the company invites a small group of its suppliers to participate in the Better Future Supplier Forum where suppliers share best practices and collaborate to reduce their emissions.

Huawei is a Chinese supplier that works directly with BT Group and helps a third of the world communicate by supplying networking parts to companies around the globe.

Since participating in BT Group’s first forum in 2012, Huawei has established a sustainability taskforce, reduced its carbon footprint 23,000 tonnes and been awarded a Silver Status Sustainability Award by BT.

“We’re hoping that our suppliers will take what they’ve learned from us and push it down their own supply chains – that’s where you get a bigger effect,” said Giner.

But before other companies can take on such ambitious work, they need to get a clearer understanding of their supply chains.

CDP recommends companies begin by making use of digital technologies that allow them to track emissions in their supply chains.

Supply chains become more efficient and responsive when they are digitized, said Galvin. It gives customers and suppliers real-time visibility all the way down the global supply chain, which can help to eliminate waste and improve efficiency.

But Galvin is quick to warn that data can’t replace direct engagement between companies and their suppliers. Digital technologies are helpful for identifying a company’s hot spots, but it doesn’t actually drive change on the ground, he said.